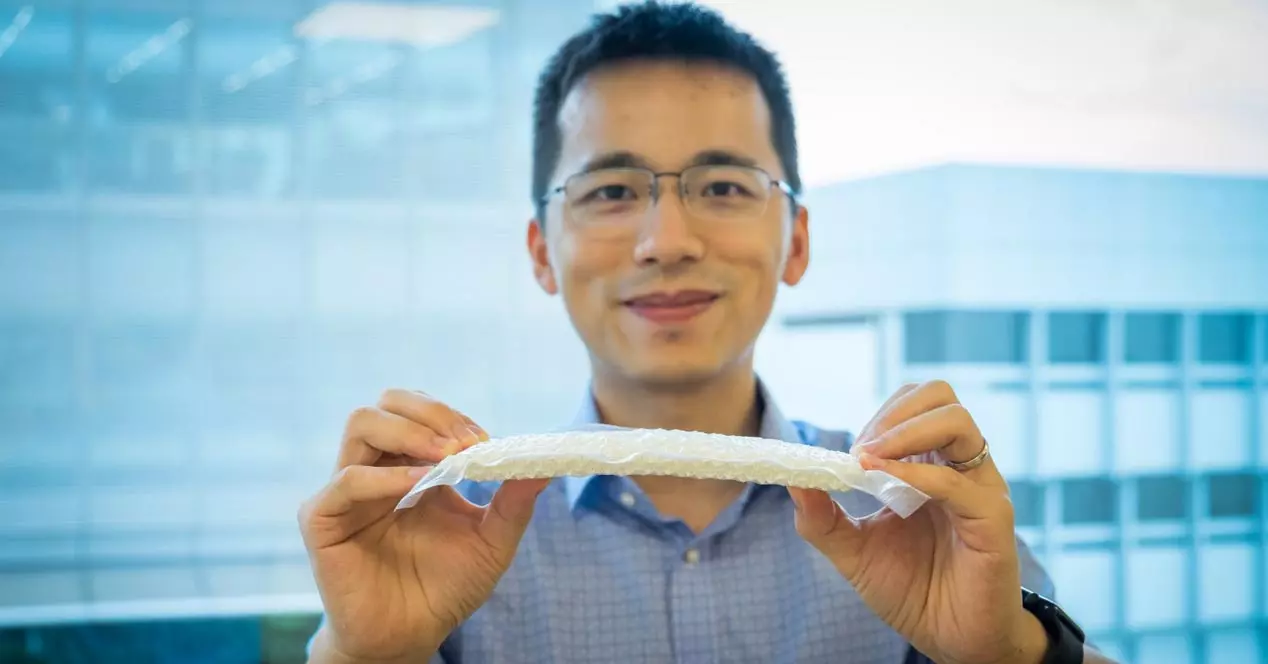

Currently there are many materials that are created artificially and have a composition that makes them better than other conventional natural materials. There are materials that have many applications such as graphene. However, a group of scientists has created a new , very resistant chainmail that can go from being highly flexible to being completely rigid.

Specifically, it was created at the Nanyang Technological University in Singapore and Caltech in the United States.

You can change its composition

The developers wanted to create a material that could go from being flexible and soft to hard with great resistance . To achieve this, research work began to see how to intertwine structured but hollow particles in order to create a hard material that could alter its composition.

Hollow plastic particles have been used that stick together to improve the strength of the material. In fact, they want to improve their hardness and rigidity even more, and they are currently working on fabrics made of different metals that could be used in industrial applications such as buildings that support a lot of weight, such as blocks of flats or bridges.

Thanks to a technique that increased the contact between the different particles designed to create the material, a hardness 25 times higher than normal was achieved. In this case it is a nylon version.

Several tests were carried out to check its condition: it was confirmed that the new material could withstand loads of up to one and a half kilograms. Or what is the same, up to 50 times its weight.

In another experiment, a tiny metal ball was dropped onto the material when it was flexible, causing it to deform a total of 2.6 centimeters. Later that same test was carried out with the material being rigid and only three millimeters deformed.

A bulletproof material

Then, using modern 3D printing technique, a version of the material was printed using aluminum, and it was found to have the same specifications as the nylon prototype. However, after it was discovered that it had much more hardness due to the characteristics that aluminum has compared to nylon.

Although the first nylon version worked well, this new metallic model is much superior and could be encapsulated with another very strong material such as Kevlar to create bulletproof vests.

But not only that, it could also have other types of applications such as exoskeletons, plasters that change their rigidity or bridges that can be deployed and hardened according to the needs.

Right now, the team of scientists is working to further improve performance. New ways of increasing its stiffness are being sought either through experiments where electrical current is applied to the material, exposure to different temperatures or magnetism.