Until the very last moment, until the last day before the presentation, there was debate about the fact that NVIDIA could have used the 7nm EUV manufacturing process to get ahead of AMD. As we saw, they finally had to opt for the 8 nm and this is a very important performance handicap compared to its rival, why did they not opt for Samsung‘s EUV technology?

The impact on the GPU market is marked by two very clear indicators: performance and price. Although it must be clarified that graphics cards for data centers break that mold, the rest do enter it, since they are aimed at the end user and not at companies.

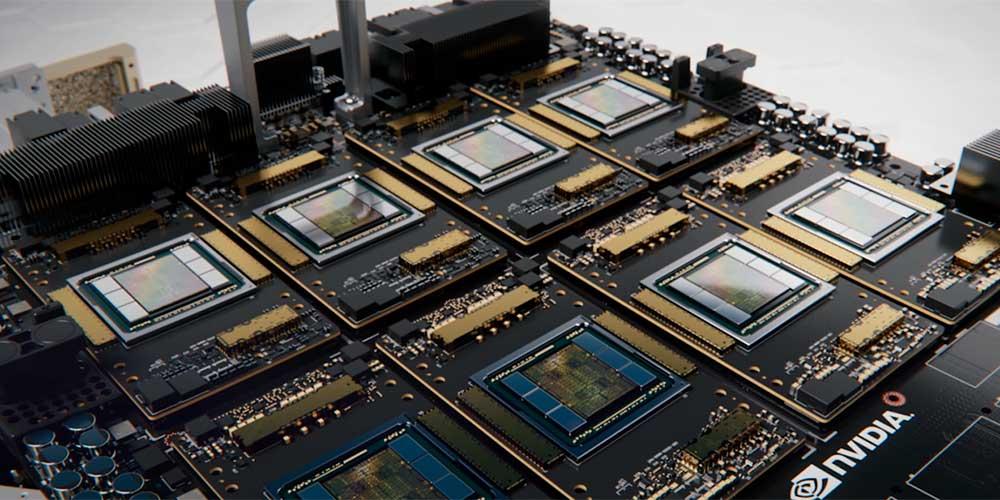

This is one of the main reasons why NVIDIA very cleverly directed its A100 chip into the hands of TSMC and its 7nm, but has not (nor was able to) leave the rest of the chips to the Taiwanese. Why choose 8nm knowing that it is a step back from its rival?

10nm bypass, lower density, lower performance, where is the advantage?

With Turing NVIDIA faced harsh criticism for the price it set for its GPUs. The problem is that there was no competition and many went through the hoop even reluctantly. With Ampere the reasons are somewhat different, since they will have competition, this being a key factor in the choice of the node by NVIDIA.

Quickly recapping, Samsung’s node is 50% worse in density than TSMC’s, performance is 15% worse on average, and yet NVIDIA has managed to include 28.3 billion transistors and increase the Boost frequency to 1, 7 GHz , but also and this is a key point, it has managed to increase the energy efficiency of each chip by 1.9x compared to Turing.

The novelties of the architecture mark the performance, for which and knowing the above, we close the chapter, but what about the price? here is mainly the advantage and the reasons for choosing NVIDIA.

The price per wafer continues to skyrocket at TSMC, and besides, there is no stock

Apple, AMD and other manufacturers have wafer reserves for at least the next 6 months in high volume orders, so NVIDIA ruled out as we discussed at the time to include the RTX 3000 under this node.

But it is also that, even if it had stock available to reserve, the price per wafer with orders of this type of volume would not fall below $ 8,000 for a 12-inch size. Depending on the number of wafers, the prices that analysts handle range from those $ 8,000 to $ 10,000, a figure that NVIDIA did not see with good eyes to compete with AMD and have enough income.

For this reason, Samsung entered the fray and although the contract is still restricted, its 8 nm process is mature, it is in high volume and also according to certain sources, the price per wafer is about 30% cheaper . In other words, in the best of cases NVIDIA would be paying $ 5,600 per wafer.

Once this doubt is solved, the “million dollar question” remains, why not opt for Samsung’s 7 nm EUV that are already in production? Precisely because of the volume. The NVIDIA and Samsung contract is estimated to be worth at least $ 1 billion , which broadly and round up is 180,000 wafers per year.

The 7 nm EUV is still residual, the 8 nm was the only option

Samsung has finished its 7 nm EUV process, but rumors claim that it is not to compete or be produced in a volume of wafers of such magnitude and that this will arrive at some point in 2021 without specifying a date.

Ergo, NVIDIA was between a rock and a hard place: it arrived late and badly at 7 nm from TSMC, Samsung could not give it volume at 7 nm EUV and thus put itself far ahead of the rest and the only node that improved at 12 nm TSMC and Turing were Samsung’s 8nm for that number of wafers.

Therefore, we are not talking about an open choice as such, but rather a need imposed by the situation of the semiconductor market, which leaves a door open for AMD to finally hit the key and take advantage of the superiority of the node. of TSMC to open space against his rival.