If we think of materials that make up a next-generation armor, two of the characteristics that these should present are their lightness and slim shape. Scientists are making a lot of progress in this regard. The latest example is found at the Massachusetts Institute of Technology, where scientists have developed through advanced nanoscale engineering a material that is stronger than kevlar and steel.

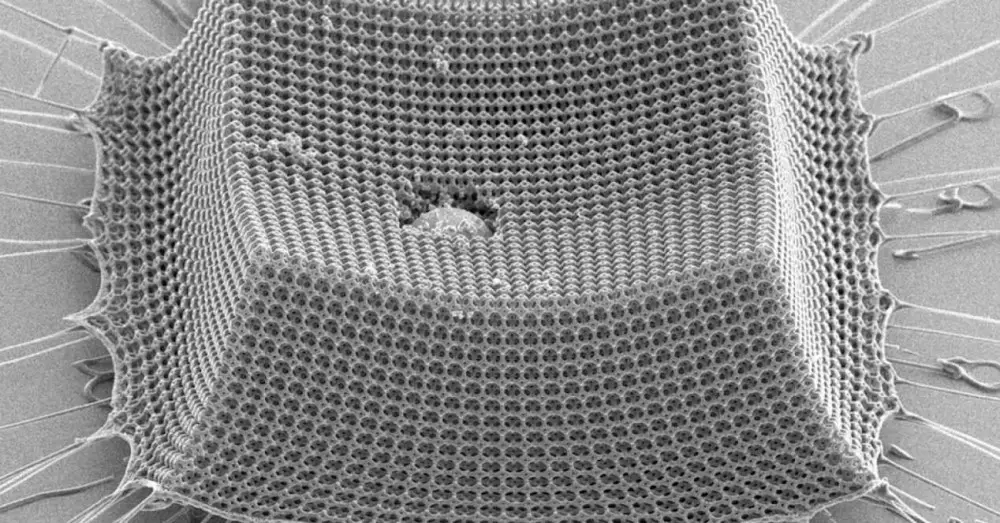

The starting point for this material was photosensitive resin, which was treated with lasers to form a lattice pattern composed of repeating microscopic dots. The material was then placed in a high-temperature vacuum chamber, causing the polymer to turn into an ultra-light carbon that resembles foams that are designed to absorb shock.

Complex but effective

Although carbon is often brittle, the arrangement and small size of the dots in the nanoarchitecture material result in a rubbery architecture in which flexing dominates. The Massachusetts team discovered that the properties of this material could be altered by adjusting its architecture.

So far , only the response of carbon in a state of slow deformation is known, while it is assumed that its application in the real world should not be slowly deformed.

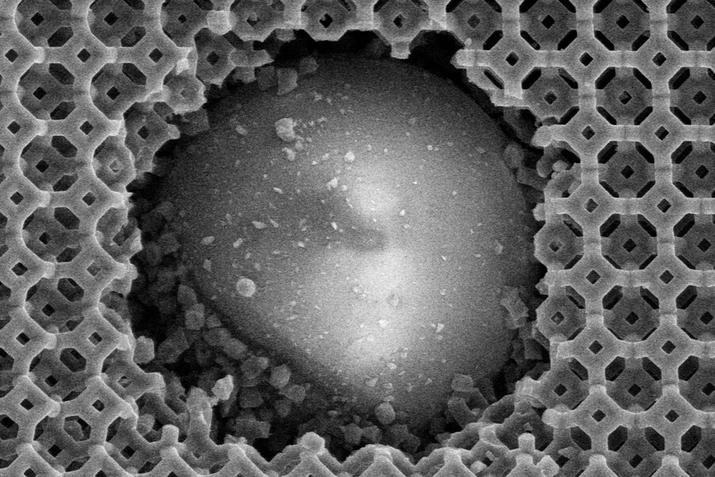

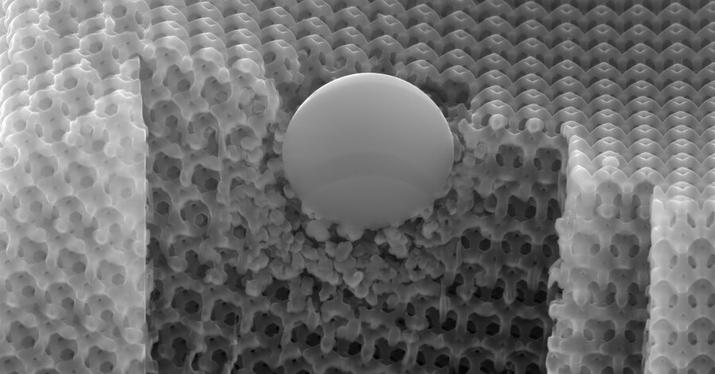

To carry out the impact experiments, various objects were involved such as a glass covered with a gold film and silicon oxide particles on one side. By applying an ultra-fast laser to this object, a rapidly expanding gas is formed that sends the particles flying from the surface towards the target. Adjusting the speed of the laser adjusts the speed of the projectiles, allowing scientists to experiment with different speed ranges , which is ideal for their studies on the new material of this armor.

The importance of carbon

In these tests, tests were carried out with supersonic speeds (from 40 to 1,100 meters per second). High-speed cameras were used to capture the maximum details of the impacts for the study. Different carbon dot designs with different thicknesses were also tested to allow the team to discover the optimal design to make the particles embed in the material rather than pass through.

The team has succeeded in showing that the material absorbs a lot of energy due to the impact compaction mechanism of the nanoscale carbon dots. They have also confirmed that this material is thinner than a human hair, so it could absorb impacts more effectively than other materials such as aluminum, steel or Kevlar. If the focus of this new material is broadened, a stronger and lighter armor than one made with traditional materials will be achieved.

Furthermore, this study could be the beginning in defense field to design ultralight impact resistant materials such as blast resistant shields, protective coatings or armor materials.