For many years it has always been said that the best blocks were those made of solid metal, mainly because it got less temperature in the CPU or GPU and then also for a security reason. And it is that the blocks used to come in “clear” format, that is to say, in plexiglass, they always had the bad reputation that they could break or cause leaks. And although it was known by many, no one ever asked, why does the plexi or acrylics crack on the blocks?

There are two explanations that go hand in hand to understand why that hardly happens in custom liquid cooling anymore. The first is the materials used, while the second goes towards the user himself.

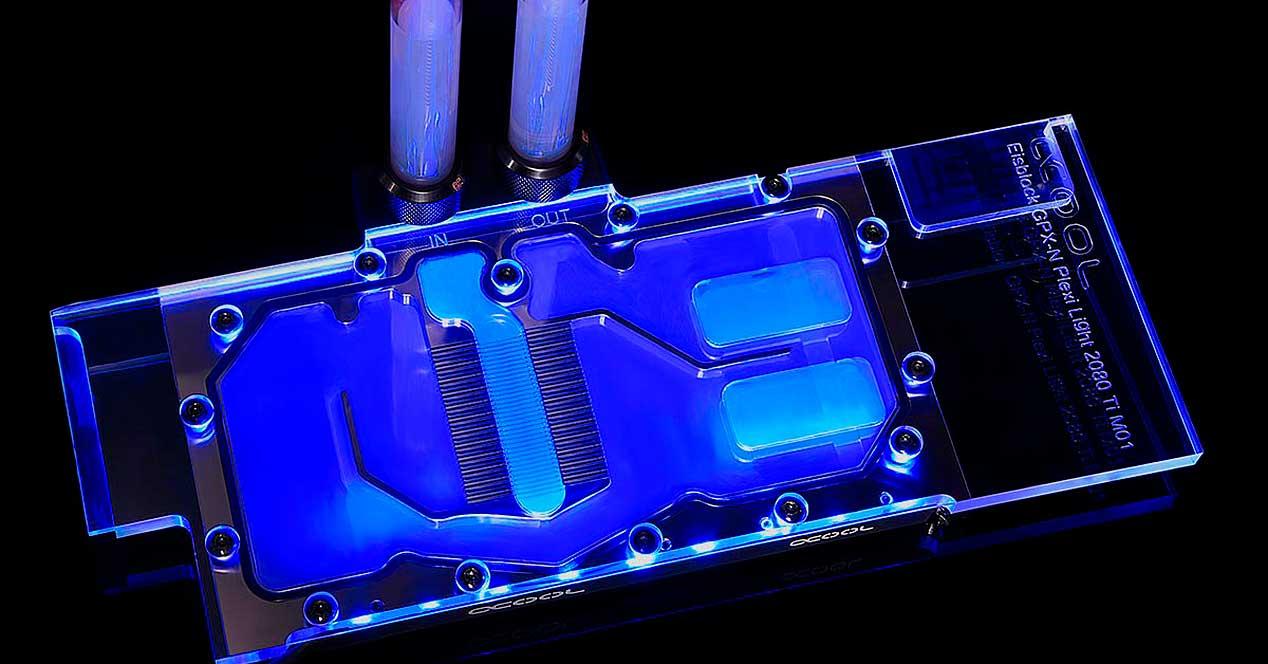

The use of extruded acrylics, the way to maintain aesthetics and save costs

Poorly machined extruded acrylic is the main culprit for cracking in custom water cooling parts. Extruded acrylic is a low-cost and easy-to-make material, which is why almost every water cooling company has been using it for years to be more profitable or offer cheaper products to eliminate competition.

But extruded plexi / acrylic is not appropriate for liquid-cooled parts, as it is prone to stress and fracture due to machining and expansion / contraction during temperature fluctuations and exposure to liquids.

But there is more, as injection molded plexi / nylon blocks (the vast majority of today’s blocks include them) have similar disadvantages, including +/- 10% expansion variation and high fluid retention, all sources of stress.

This is the main reason why from the point of view of the materials, we can suffer cracks or directly breakage of the used acrylics. We are now going to know the point from the user.

Malpractice, the main problem that can be avoided with the plexi

Torsions and temperature changes, as we have already seen, affect a material as weak as acrylics, but if we also combine it with the misconception of: the higher the pressure, the less possible leakage , then we have a cocktail ready to explode, literally speaking.

That is, the concept of tightening to the limit is used by many thinking that it is the right thing to do, but the reality is that any fitting that we install already has an O-ring that precisely prevents the leakage of the liquid and it will be enough to tighten it firmly nothing else.

With this it will be more than enough to be sure, the acrylic will not suffer excessively and thus we will avoid from cracks in cobweb, to breaks, fissures and others. Knowing this, we could ask ourselves about what type of acrylic is the one we have to look for in a liquid cooling block. The correct one, or at least the hardest, is cast acrylic, since it is so hard that it is used even in aquariums as a substitute for glass, so it has to withstand enormous pressure.

In fact, it is so strong, that it is harder than acetal and almost unbreakable, the problem logically is that it is more expensive to manufacture and the blocks skyrocket in price a bit.