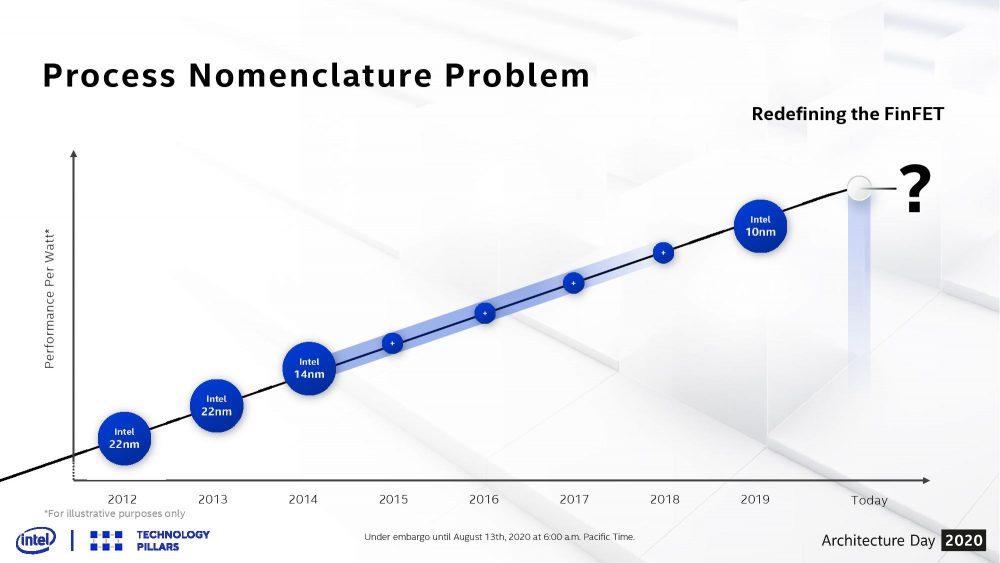

For those interested in the semiconductor industry – and processors within it – it has been hard to miss the recent news about problems in Intel‘s manufacturing process. In short, the brand’s 10nm lithography has not lived up to expectations in terms of performance, it has arrived a couple of years later than it should and has no capacity to compete in the market. Thus, Intel has opted for an approach to 10 nm from a different perspective than what they have called SuperFin , which we are going to explain below.

Even months after launch, Intel’s 10nm processors have a very low production volume, and Tiger Lake is expected to be the first true example of what Intel’s 10nm vision was supposed to be. .

Intel’s manufacturing processes

Before we get down to business with SuperFin, let’s see a bit of the history that led to its birth. The next step of the foundry change in Intel manufacturing, the move to 7nm with EUV (Extreme Ultra Violet) technology, is also delayed (announced by Intel itself). With news like this, Intel is struggling to maintain confidence that they can launch an industry-leading manufacturing technology that is competitive in the market. This used to be the position that Intel held until problems and lags started with its 10nm node.

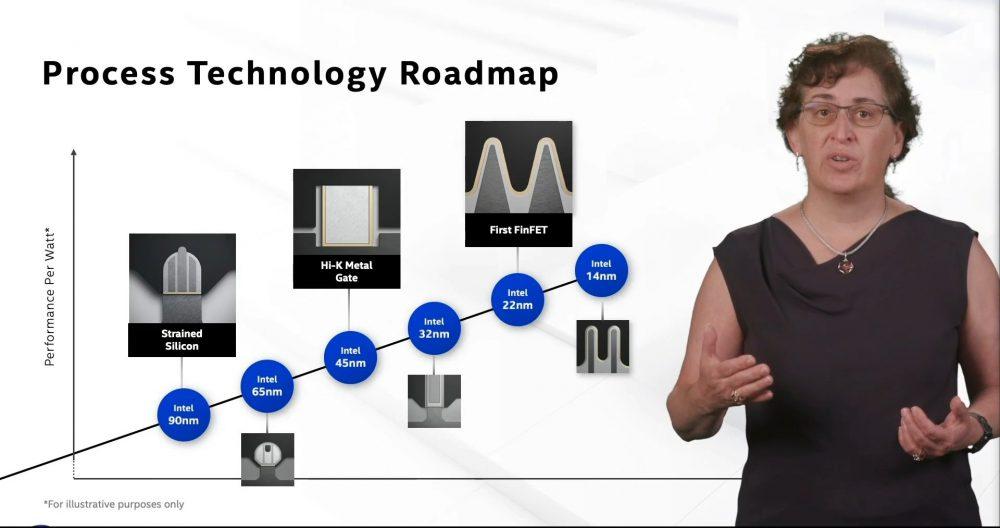

Intel’s disclosures about its manufacturing technology vary in complexity depending on how successful the product is internally. When they first announced the FinFET process on their 22nm node in May 2011, there was a lot of information already from the beginning and the node was very successful. With the next generation, the 14 nm, there were some delays with the initial generation of processors (Broadwell) but finally the company explained the process in detail at an event of its own, around August 2014.

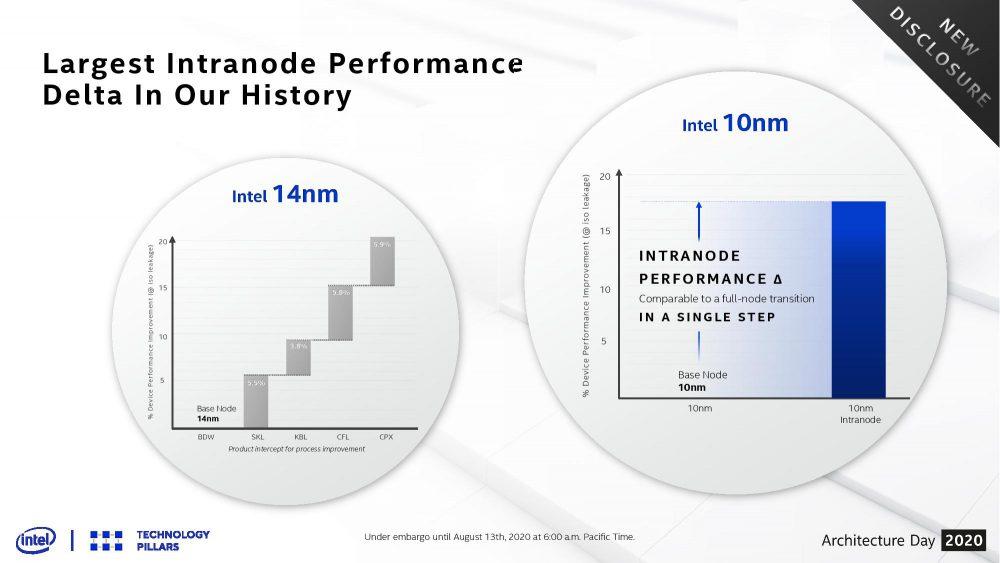

The 14nm process node has been Intel’s most profitable to date, and continued intranode improvements over the years demonstrate this (14+, 14 ++, 14 +++, 14 ++++ ), giving the business an efficient upgrade equivalent to a pure node upgrade within a single generation of processors.

When we talk about 10 nm, the situation is however not so optimistic, even if we compare it with the delays suffered at 14 nm. To date, Intel has had two generations of 10nm CPU products, one of which the company avoids even mentioning in public. Cannon Lake, the first product at 10nm, made its way into the brand’s Crimson Canyon NUC mini PCs, and it was a disaster: only two cores, no integrated graphics and although they included it in the 2017 revenue report, the company quickly discontinued it.

Ice Lake was the right shuttle for Intel at 10nm, offering four cores and good Gen 11 integrated graphics with just 15W TDP. It has found its way into more than 50 notebook designs, but despite offering a gross performance increase of up to 20% clock-to-clock, the 10-20% decrease in clock speed has made the final improvement. be insignificant. Ice Lake graphics are still much better than 14nm, and support for Thunderbolt 3 and 512-bit vector instructions has still made a positive point nonetheless.

In its current form, because Intel does not want to see Cannon Lake as a real part of its heritage, Ice Lake was considered a flat “10nm” product with no additional benefits. Later, Ice Lake became Tiger Lake, built on a node called 10+.

Intel SuperFin Technology

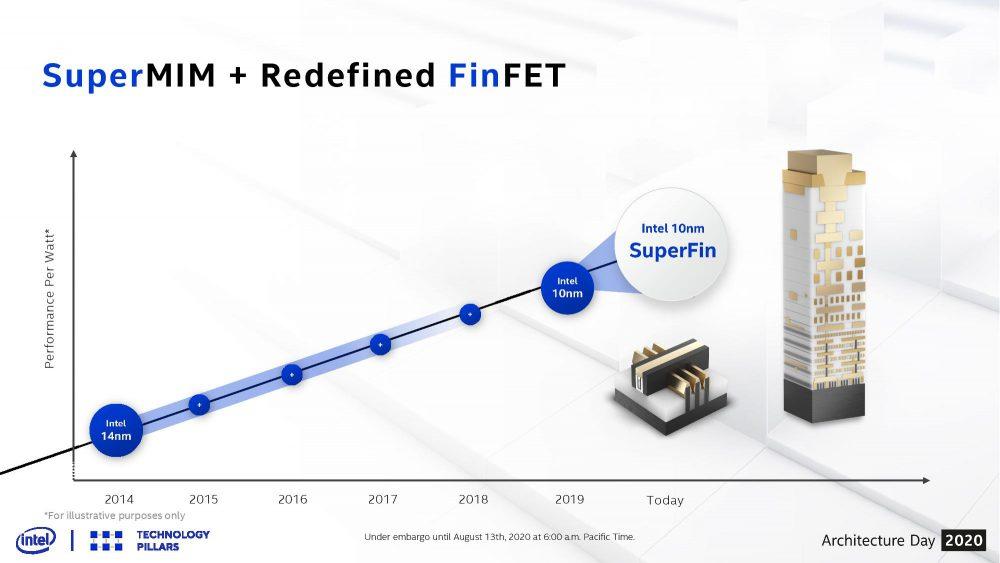

SuperFin technology at 10nm is what the Tiger Lake architecture is based on, and represents the new 10+ name for its lithography.

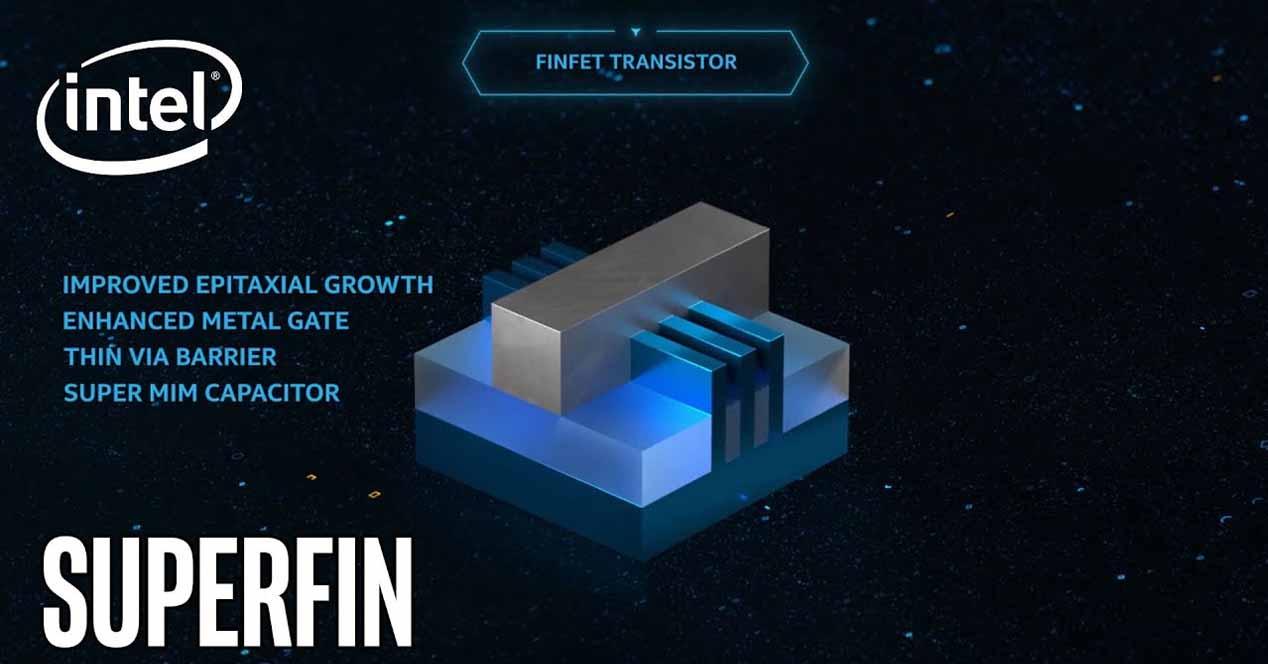

As part of Intel’s 10FS process, we’re going to take a look at what makes this different from 10nm Ice Lake, as well as updates on some key parts of the transistor design that make up this process, and what they have done. that Intel claims they have redefined the way they make transistors.

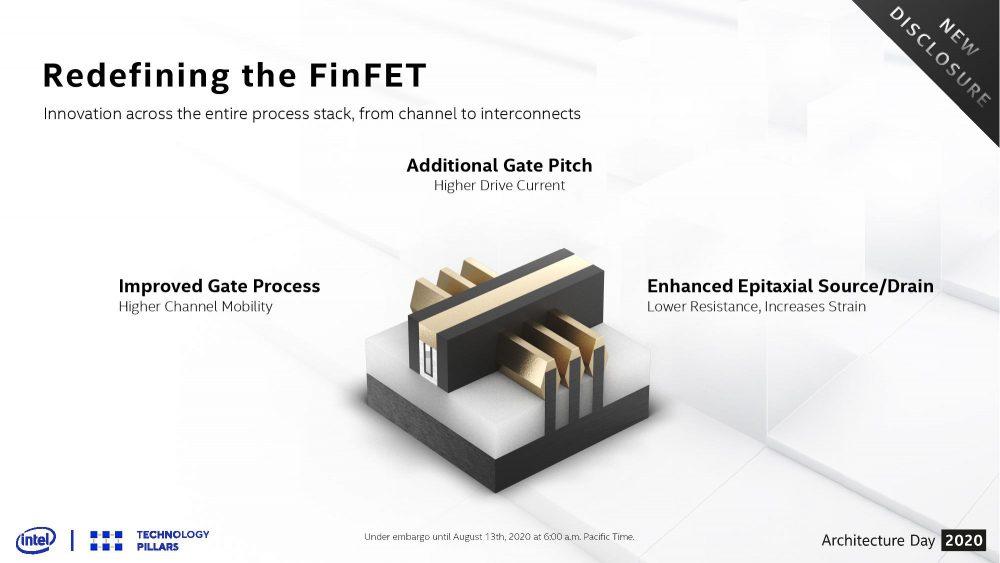

10SD builds on 10nm by introducing a redefined FinFET design (4th generation?). With higher performance per Fin and a new SuperMIM (Metal-Insulator-Metal, Metal-Insulator-Metal) capacitor design, the SuperFin design focuses on three areas:

Through new fabrication techniques, the epitaxial growth of crystalline structures in the source and drain has been enhanced, increasing the strain to reduce resistance and allow more current to flow through the channels.

An improved source / drain architecture and an improved transistor gate manufacturing process help drive more additional channel mobility, allowing charge carriers to move faster and improving the performance of each of transistors.

Additionally, a larger gate pitch to allow a higher drive current for certain chip functions also helps improve performance. Normally a larger gate step would sound like the transistor is too, and yet making the transistor larger with improved performance actually means fewer buffers are needed in high-performance cell libraries and, ultimately the cell size is decreased as a result.

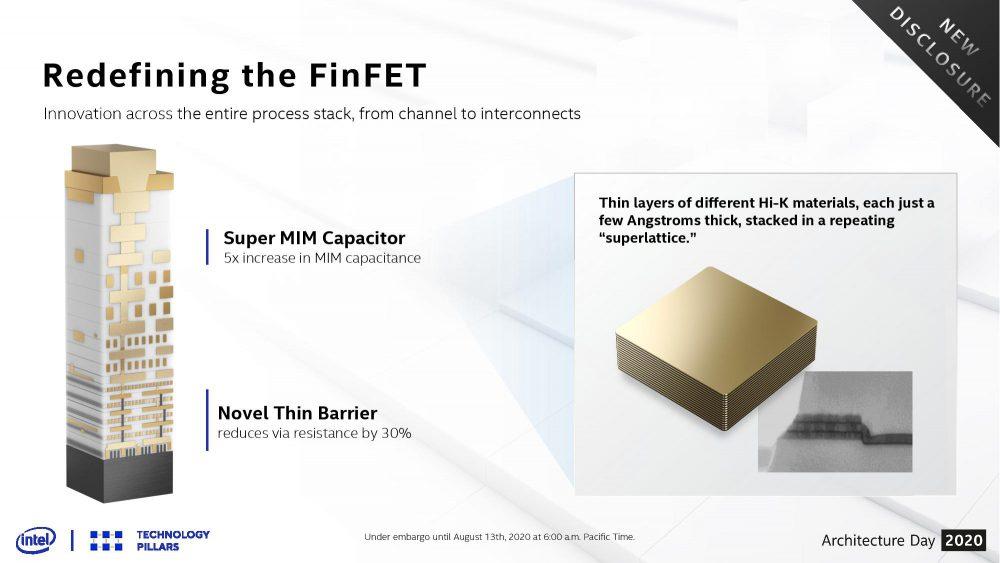

As for the metal stack, Intel makes some claims that we could call “bold” and that involve some pretty interesting technology.

In the lower layers of the stack, Intel introduces a new set of barrier materials that make them thinner, which also helps reduce the resistance of the tracks by up to 30%, allowing the metal in each to have a proportion greater flow. The reduction in resistance improves the performance of the interconnection between metal layers.

Another improvement in this SuperFin process is that at higher levels, Intel introduces the new SuperMIM capacitor that we discussed earlier. According to the manufacturer, this new design offers a 5X increase in capacitance over an industry standard MIM limit while occupying the same space.

This generates a voltage drop that ultimately leads to dramatically improved product and transistor performance. Intel claims this is an industry leading design, enabled through the careful deposition of new Hi-K materials in thin layers, less than 0.1 nm, to form a kind of “super grid” between two or more types. of materials.

Taken together, Intel claims that all of these SuperFin features represent the “biggest improvement in Intel’s history,” and allow 17-18% higher transistor performance from 10nm designs. This makes the 10SF process equivalent to a full node-wide upgrade over Intel’s base 10nm process. To draw a parallel to the 14nm mark, 10SF is the equivalent of Coffee Lake (14 +++) to Broadwell (14nm).