The PC industry is always trying to find new goals to improve performance, temperature or consumption. In basic thermodynamics there are a number of effects that could help with this, but they have a number of limitations that have not yet been resolved, but that could be under study. One of them is the so-called Thomson effect , well known and has great applications on PC, but why not use it?

Anyone who has studied any branch of thermodynamics will know this effect and as such will have asked on more than one occasion why the industry has not continued to invest resources in alleviating its negative points.

Next, we will know the basic points of it and everything related to its branch for computing, since there have been serious attempts to put it into practice and of which we currently do not know anything.

Thomson effect, as effective as it appears?

Studied by the man who gives it its name, Willian Thomson in 1851, where it was first predicted on paper and then empirically demonstrated, we talk about an effect that has serious connotations for the PC industry and just a couple of problems to solve.

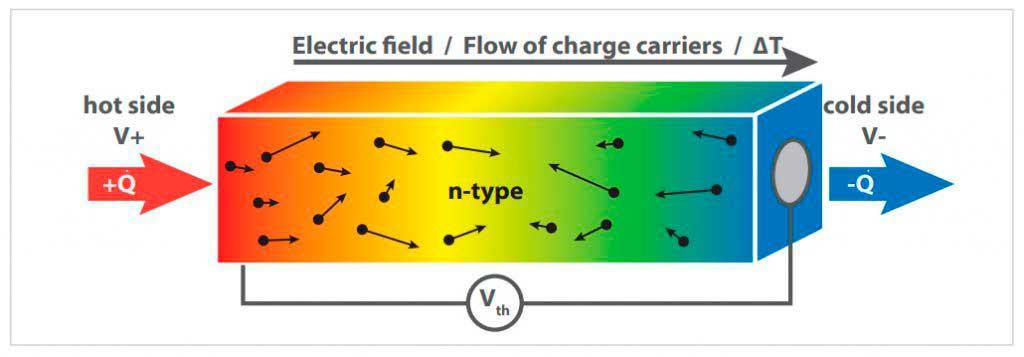

This effect is based on a current-conducting material as a base, which is heated or cooled by passing it with a temperature gradient, that is, the effect tries to explain how a current-conducting material can be heated or cooled with the passage of it between two points.

Many of you will already have a raised eyebrow and a lit bulb above your head, and that is that the effect lets itself be loved as soon as it is known, but before looking at its possible applications, we must know that there are two types of Thomson effect: positive and negative .

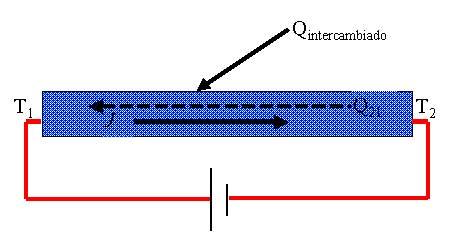

The positive is based on moving the current from the hot end to the cold end, that is, it moves from a high potential to a low one and thus produces heat. The negative effect is just the opposite, we have a cold end and a hot end with a lower potential, where the current will move from low potential to high and with this, heat is absorbed.

Having understood this, we can only understand that this effect, unlike the other two that we saw at the time, is the only one that can be measured in individual materials, something that we will need to develop our ideas.

Why is it not used in CPUs and GPUs?

Just as the CPU and GPU heatsink fans are powered, logic tells us that we could enhance the negative Thomson effect by applying power to a material such as nickel or copper where the cold plate is the of greater potential, and thus placing it together with a die or IHS would manage to absorb more heat from the chip.

Although it was little current as expected and being the system feasible from the theoretical point of view, where the temperature gain would have to be seen when using it, there is a factor that prevents it and which in turn is divided into two different arguments: the Silicon is a superconductor in any current processor.

The quality of the silicon, its pure composition, the treatment and creation of the wafers and the die result in that the PC and server chips are truly superconducting by all accounts. Why is this relevant? Because, even if the Thomson effect were applied to a heatsink or block, the electric current will end up leaking into the superconductor, causing damage to the die.

The nanometric scale we are in stipulates impedances, jitter and an endless number of extremely precise electrical parameters for a current die. The Thomson effect would implement an external overcurrent that would end up annihilating said die and therefore leaving us with a nice paperweight.

Electrically isolating dies is not physically possible

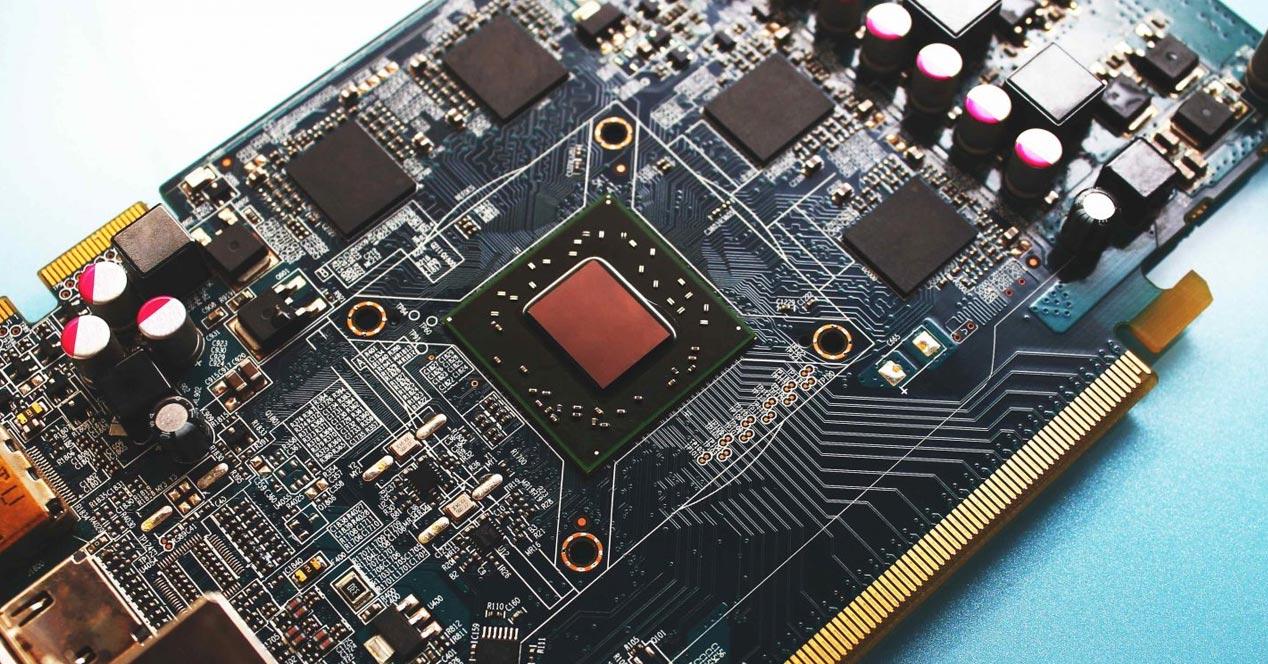

What if we isolate the die with an IHS? That attempt has not been lacking in the industry, where several prototypes have tried throughout history. The problem is that the compounds to seal the IHS are not totally immune to the electric current, since a single component based on a bypass carbon is used, so some leaks will end up on the PCB ( copper, cobalt and copper layers). zinc ) where they will again seep into the die.

We have to take into account the high sensitivity of the current die, where the simple static electricity produced by a fan pushing the air towards the fins of the heatsink already causes problems in some GPU models with the die exposed. Therefore, liquid metal thermal pastes should not be used in graphics cards, because at the minimum current leak we can literally fry the chip.

Same case for CPUs that are uncovered to contact the die with the block or heatsink, since, although water cooling only includes the fans in the radiators and the liquids are prepared to conduct electricity in minimum values, the coefficient of Friction of the same with materials such as nickel or copper produce small charges that must be considered, especially after operating time and more metal ions in the liquid.