Our mobiles are full of features and very varied technical characteristics. Every time a mobile is presented, it is not uncommon to mention “Gorilla Glass ” as part of these features, something that we never overlook on our site. It is an important element to ensure greater resistance, but what exactly is it? How is this made? Where does it come from and how does it end up on our smartphones?

Apart from the protectors and covers that we can put after buying the mobile, the manufacturers also do part of this work for us, protecting the mobile against bumps and scratches . It must be remembered that a simple fall can be fatal, since in addition to the classic and necessary glass of the screen, some privileged mind came up with a good idea that it would be a good idea to create the back parts of our glass mobiles, so they are more than likely to break at the slightest blow of consideration.

Protecting from bumps and scratches

This is where Gorilla Glass comes in, a protection sheet that can go on the front and back of our mobile, and that has been implanted by different manufacturers for more than 10 years. This film resistant to bumps and scratches is manufactured by Corning Inc, and though he began developing in 2005, the official start began in 2008, increasing concretes popularity from 2020. This increase in popularity as nswer r industry to need to protect ever larger screens. This makes the protection available on mobile phones, but also on other products such as tablets or laptops.

How is this made?

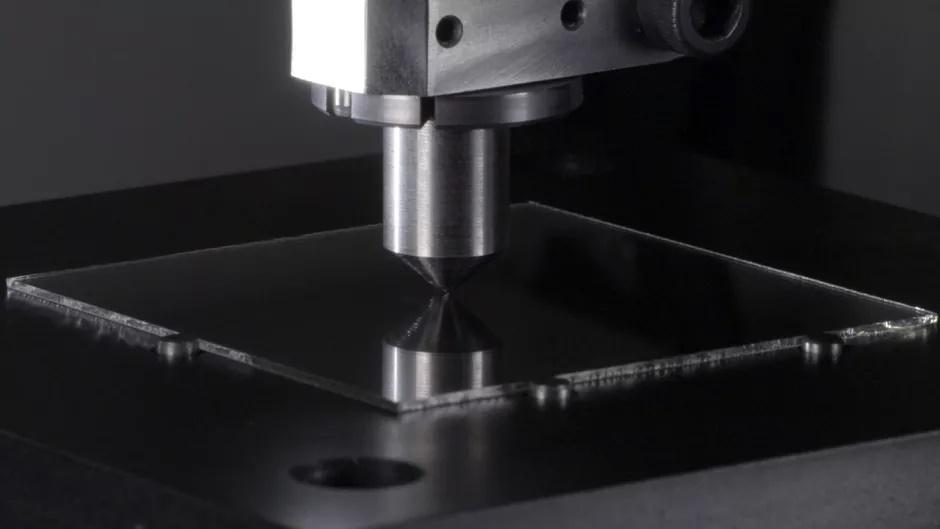

Gorilla Glass protection sheets are made of a glass made of aluminosilicate , which is a mineral composed of aluminum oxide and silicon dioxide, two materials naturally present in nature, in abundance. By using feldspars as raw material, a special composition of an artificial glass, light, thin and resistant to damage and scratches, is achieved, which can have a thickness of approximately 0.4mm. This material must be heated to high temperatures (over 400 degrees) in a mold, and then extracted and cooled, giving the shape that the protective sheet will finally have.

Gorilla Glass versions

Gorilla Glass 1 (2007)

It was the protection of the first Apple iPhone and was 1.5mm thick, and it was already accompanied by a special oleophobic coating that repels fats to reduce fingerprints and smudges on the screen.

Gorilla Glass 2 (2012)

The evolution of the sheet managed to reduce its thickness by 20% , reaching 1.2mm, increasing the resistance with pressures of up to 50kg. It was installed in more than 600 million terminals.

Gorilla Glass 3 (2013)

In the next version, the shock and scratch resistance increased by 35%. It also integrated NDR (Native Damage Resistance) technology.

Gorilla Glass 4 (2014)

The next version increased the resistance to falls and drops even more. It also improved its anti-fingerprint repellent film.

Gorilla Glass 5 (2016)

The fifth version is still widely installed even in the middle of 2020. It increased its resistance up to four times and can withstand falls of up to 1 meter in height.

Gorilla Glass 6 (2018)

This version continues to be installed in the main high-end mobiles on the market. It reduces its thickness once again and is again twice as resistant as the previous version, withstanding up to 15 consecutive falls from a height of one meter.

Gorilla Glass Victus (2020)

This year the so-called Gorilla Glass Victus, also known as Gorilla Glass 7, has been presented. It has been released in the Samsung Galaxy Note 20 Ultra and has a thickness of only 0.4 millimeters . This new version withstands drops of up to two meters and increases its resistance to bumps and scratches four times more.