We are used to the fact that in each leak or each time a new chip is presented, be it CPU or GPU, we look at the die and we always see the same thing: it is rectangular or at most square. If we take history we will see that there have hardly been chips with shapes outside of these, such as round or oval, with curves. Why are chips made like this if they come from circular wafers?

To understand this we have to understand something that we have already explained in other articles and on other occasions, so we will do it in a superficial way: how to make a wafer or in a conventional way, where do the chips come from?

Wafers, their composition, their manufacture and shape are to blame

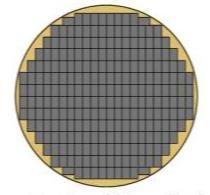

300mm (left) and 450mm (right) wafer.

Any current semiconductor is made of a very specific material such as silicon dioxide, although it includes other compounds to a lesser extent, it is true, but the majority base is this.

When compacting it and turning it at high speeds in tubas, the so-called monocrystalline silicon rods are obtained, very thick and long, like a large cylinder, which are then cut into very thin slices that are finally the wafers that we are so used to seeing.

As is logical and starting from a cylinder, the wafers when cut are round, perfect, but they will be more so after a series of very complex processes such as ion implantation, electroplating etc …

And here comes the interesting thing, because that wafer is going to be cut into the chips that will finally reach the processors and graphics cards, so at first and being round, common sense could play a trick on us and think that cutting the chips in the same way it would be the right thing to do, but no, it is rather the opposite.

More chips per wafer means more profitability and lower costs

A round wafer with current manufacturing processes at so few nanometers has to be used to the maximum, up to its physical limit. Therefore, the way to get a greater number of chips for each wafer is to cut them into rectangular or square shapes, depending on the chip and its structure, the elements it integrates and its architectural arrangement.

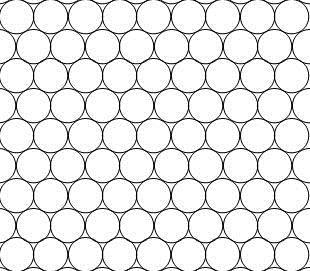

Cutting a chip round means that a minimum surface area is wasted between each circle, but overall this is a much higher percentage than cutting chips with vertices. If we add to this that cutting in circles is more expensive than doing it in a straight line, we have all the ingredients so that the industry does not design circular or curved chips.

It is true that cutting the chips in a straight way wastes the edges of the wafers, either because it catches in the middle of a chip, or because a complete chip cannot be removed. But in general terms, more surface area is still used in a straight line than in any other simple geometric shape.

Chips could be made with other geometric shapes that imply making better use of each wafer, the problem is the same as in the circular case: costs. The designs would be much more complex, the cut would be more complicated and ultimately the price of each chip would increase, which we do not want since the wafers are already skyrocketing and it is something that has a direct impact on the final buyer.