Various types of materials are used in the production of filament spools for 3D printers. Each material presents distinct properties and characteristics, accompanied by specific usage requirements. Prior to acquiring a filament, it’s imperative to understand its melting point as well as the temperature range achievable by the 3D printer’s nozzle.

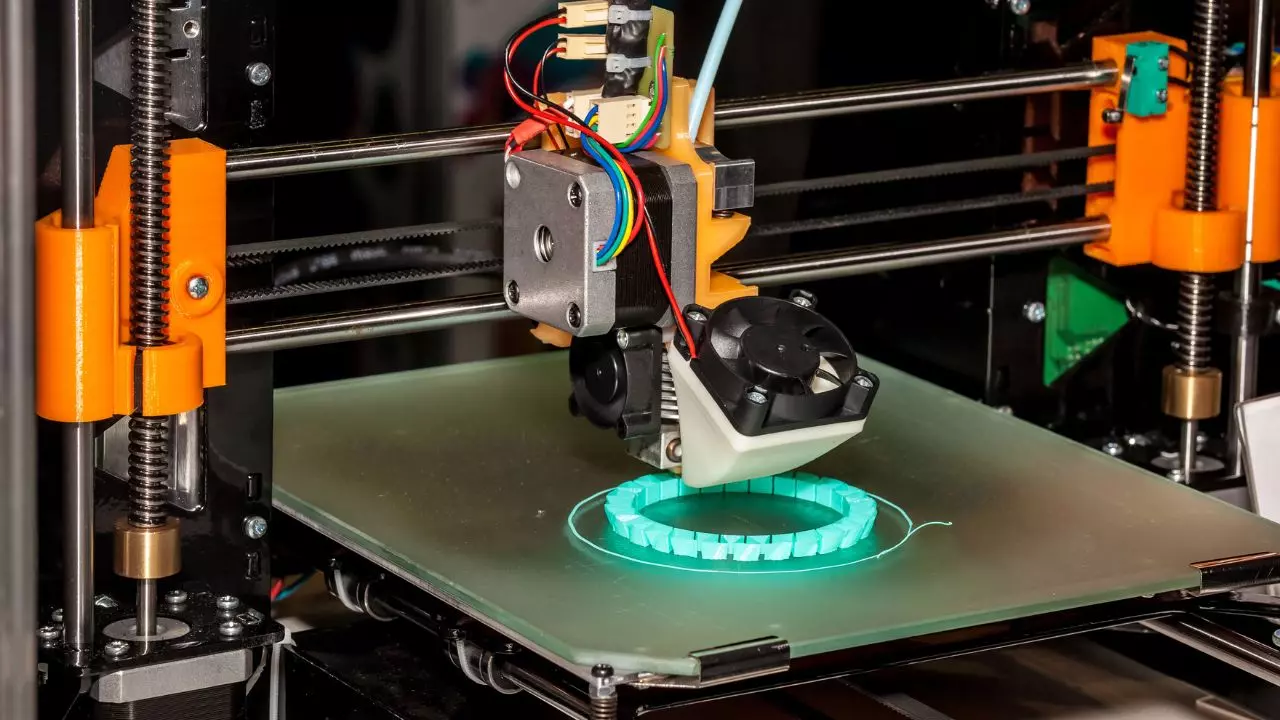

In terms of functionality, 3D printers operate with a certain degree of simplicity. Upon uploading a 3D design, the printing process commences. The filament is drawn into the extruder, undergoing heating before emerging from the nozzle. Guided by the provided design file, the printer orchestrates its movements to craft the desired object.

One common oversight involves neglecting the compatibility of nozzle and filament temperatures. Nozzles come with an upper temperature threshold, while filaments have specific melting temperature ranges. A mismatch between these temperatures can lead to complications, particularly when the material’s melting point exceeds that of the extruder nozzle.

Temperatures of the different filaments

Prior to acquiring a filament for your 3D printer, it’s crucial to acquaint yourself with both the material’s melting temperature and the capability of your extruder nozzle. Overlooking this critical aspect can lead to disastrous outcomes. Exceeding your printer’s temperature limitations can result in issues like filament jams, potentially necessitating the replacement of the entire extruder, or yielding defective prints.

In a bid to assist you in navigating this challenge, we’ve compiled the melting temperatures of various filaments. It’s of paramount importance that you always scrutinize a filament’s specifications before making a purchase, ensuring that the material’s melting temperature is clearly indicated. In cases where this information is absent, it’s advisable to seek an alternative seller, as this parameter holds substantial significance.

Allow us to provide you with insights into the melting temperatures of the most common filament materials and their respective temperature ranges.

PLA (polylactic acid)

Currently, PLA holds the mantle of popularity due to its user-friendly nature, eco-friendliness, and biodegradability. Derived from corn starch, it boasts a melting temperature that spans from 180 ºC to 230 ºC. This temperature range makes it universally compatible with all available extruders in the market.

ABS (acrylonitrile butadiene styrene)

Equally renowned, ABS finds widespread use in industries like mobile phones and automobiles. Notably flexible and resistant to impact, it endures temperatures ranging from -20ºC to 80ºC following proper handling.

However, this material presents certain drawbacks. First and foremost, it is toxic, necessitating usage within well-ventilated environments or enclosed 3D printers. It demands melting temperatures between 210 ºC and 250 ºC. It’s worth noting that ABS has a tendency to deform as it cools, potentially affecting the quality of the printed piece.

PETG (polyethylene terephthalate)

Hailing from the same material as supermarket plastic bottles, PETG is an inert choice ideal for food-contact applications. Offering commendable resistance and semi-rigidity, it doesn’t emit odors during printing. Its recyclability has led many to repurpose bottles for cost-effective filament. The preferred source is often the blue bottles of a well-known water brand. This material’s melting temperatures fall within the range of 220 ºC to 250 ºC.

Nylon

Nylon presents an intriguing filament option, primarily celebrated for its remarkable combination of hardness, flexibility, and durability. It finds frequent use within industries but does come with the challenge of requiring open spaces for safe utilization. Its operational temperatures range from 240 ºC to 260 ºC.

PC (polycarbonate)

Prominent in engineering applications, PC boasts high-temperature resistance, albeit with the drawback of absorbing moisture from the atmosphere. This peculiarity necessitates hermetic storage to maintain its performance and strength. PC’s major challenge in 3D printing lies in its melting temperature requirement of 270 ºC to 310 ºC.

TPU (thermoplastic polyurethane)

A highly flexible and robust material, TPU finds applications within the automotive sector. Deriving from rubber (TPE), it offers amplified rigidity and durability, commonly employed in crafting smartphone cases.

An advantageous aspect is its melting temperature requirement, which falls within the range of 210 ºC to 230 ºC, aligning quite closely with PLA.

ASA (acrylonitrile styrene acrylate)

ASA bears resemblances to ABS in terms of characteristics and properties but showcases augmented resistance to UV radiation. This renders it an excellent choice for outdoor components, although it tends to absorb a significant amount of moisture. Notably, ASA is also toxic, demanding usage within well-ventilated spaces or enclosed 3D printers.

Two variants exist, each influencing the melting temperature:

Unannealed: ranging from 77ºC to 102ºC

Annealed: spanning from 88ºC to 104 ºC

Summary of filament melting temperatures

| Material | Temperature |

|---|---|

| PLA (polylactic acid) | Between 180 ºC and 230 ºC |

| ABS (acrylonitrile butadiene styrene) | Between 210 ºC and 250 ºC |

| PETG (polyethylene terephthalate) | Between 220 ºC and 250 ºC |

| Nylon (nylon) | Between 240 ºC and 260 ºC |

| PC (polycarbonate) | Between 270 ºC and 310 ºC |

| TPU (thermoplastic polyurethane) | Between 210 ºC and 230 ºC |

| ASA (acrylonitrile styrene acrylate) | Unannealed: 77ºC to 102ºC Annealed: 88ºC to 104ºC |

Conclusion

Prior to procuring a filament, familiarizing yourself with its specific melting temperature is crucial, as not all filaments share the same characteristics. Equally important is understanding the maximum temperature that the extruder nozzle can attain. If the nozzle temperature surpasses that of the filament material, adjustments can typically be made with ease. However, a scenario where the nozzle temperature is lower than that of the filament can lead to dire consequences.