We take for granted that plastic is the main material with which most PC peripherals are made, but when it comes to keyboards, the keys or their keycaps can be made of different types of plastic , and it depends on the materials used the keyboard will have more or less quality and, of course, durability . In this article we are going to tell you about the different types of plastic that are used to make keyboards , so that you can recognize them and evaluate in advance whether or not a keyboard is of good quality before buying it.

It is really quite difficult to differentiate at first glance if a plastic is of one type or another, since as a general rule this plastic is always tinted black or other colors, so if the manufacturer does not specify which type they have used it is difficult to find out. However, they all have some characteristic features that can help us to recognize them even without the manufacturer specifying it; Obviously, if the manufacturer tells us what are the materials with which they have made their keyboard, that will help us better to evaluate its quality.

The different types of materials used in a keyboard

The keyboards are not made only of plastic, and even if we omit the electronic part that obviously cannot be made of this material, in the same keyboard we can find different types of plastic depending on whether we are talking about the structure, the legs or the keys. , for example. Obviously, most use rubber for the legs in order to avoid slipping, but that is not that it has much to do with quality and durability, or at least not as much as when we talk about the keys, which is what we are ” crushing “literally all day long and on which durability largely depends (obviously also on the switch, but we’ve already talked about them at length).

ABS plastic, the most common and the cheapest

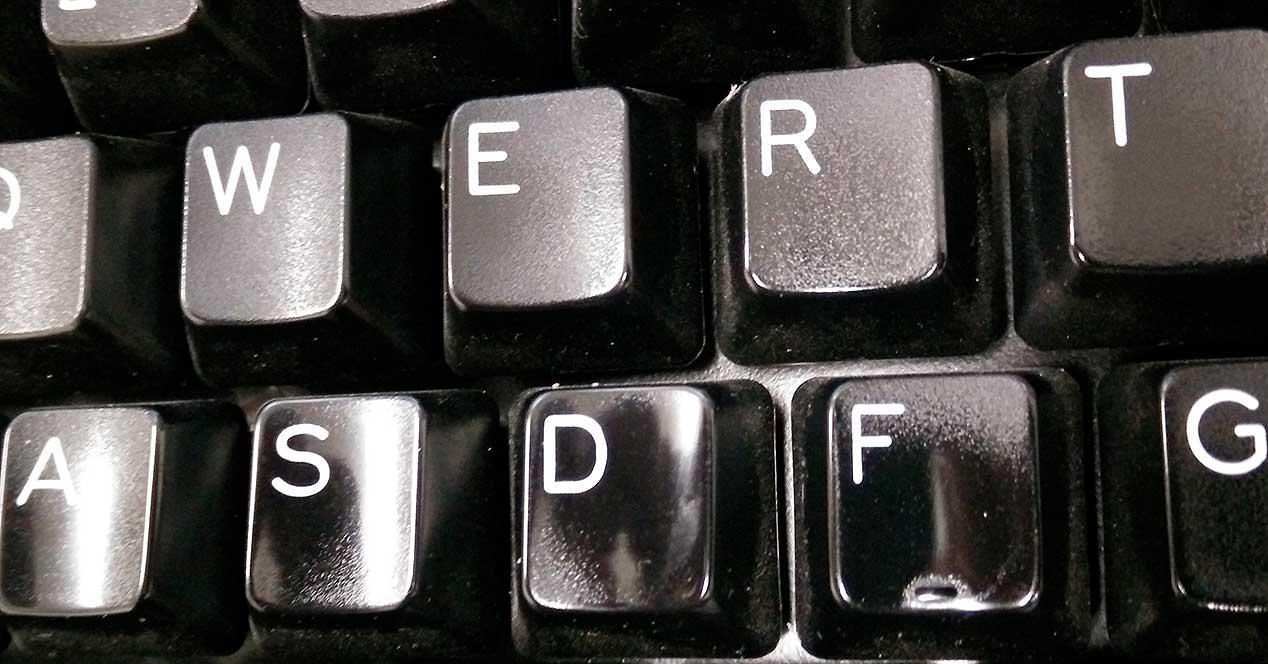

ABS is the acronym in English for Acrylonitrile Butadiene Styrene, and it is the one we most frequently see in both keyboards and other PC components (and most commercial plastics, even LEGOs are made of this material), since it is one of the cheaper to make, and fairly reasonable in strength and durability. Of course, ABS plastic is a comparatively much softer material than other modern plastics, and it also has a slightly slippery feel to the touch.

It’s not that a keyboard made of ABS plastic is bad, since as we mentioned before it has quite decent strength and durability, but it is obviously on the lower end of the scale if we have to compare it with other plastics that are also used in the industry. Of course, the use of this type of material in a keyboard also makes its price much more reasonable because it is very cheap to manufacture and mold.

PBT, stronger but more expensive

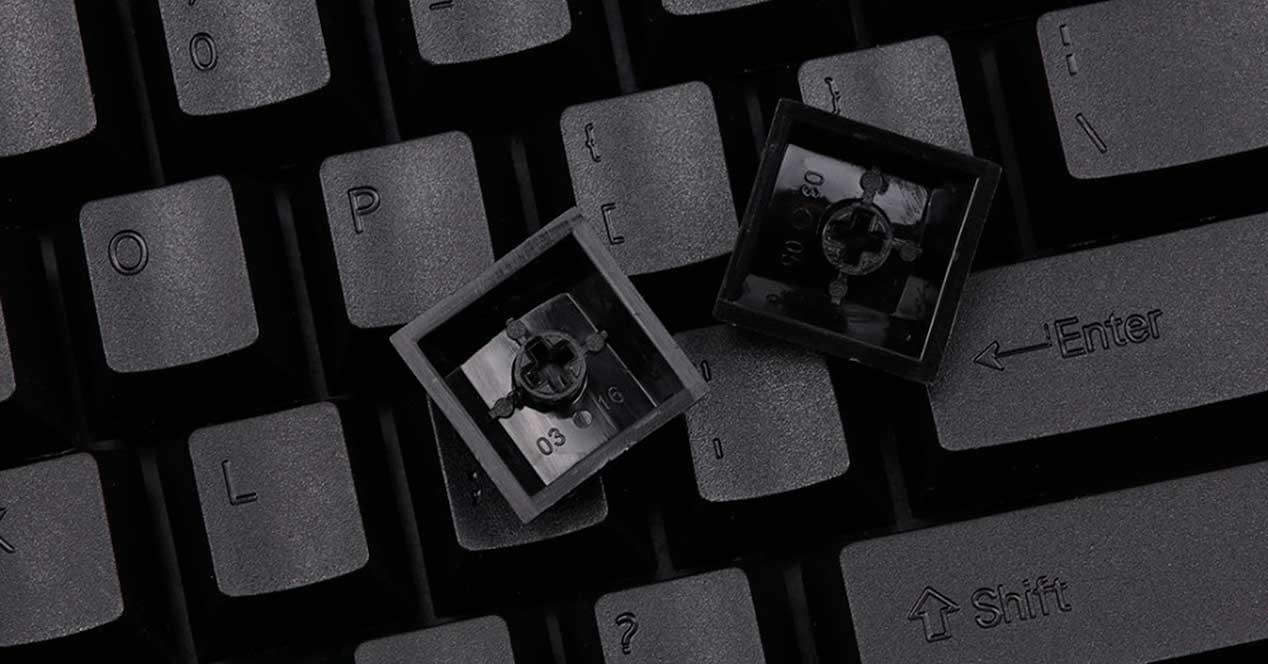

PBT comes from the acronym in English PolyButylene Terephtalate or polybutylene terephthalate, and is a harder and more resistant material than ABS. It wears much less and tends less to “yellow” over time, although one of its disadvantages is that it is significantly more expensive to manufacture and not many manufacturers use it in their keyboards (currently, only some Cherry, Poker, Leopold keyboard models and IBM).

Another disadvantage of this material (which for many it is not) is that it has a less smooth and gritty touch; Many users dislike this and others like it because it literally has more grip, and for a gaming keyboard, for example, the use of these materials makes sweating less noticeable. However, in addition to this and the higher price, the main disadvantage of this material is that it is more brittle and can be broken more easily by bumps and drops.

POM, the most resistant of all

POM stands for Polyoxymethyleneor or Polyoxymethylene, but it is better known by its trade name: “Delrin”. This material is very resistant to abrasion and solvents, as well as wear, and its properties also make it have very low friction. However, the trade-off of this material is that it is very expensive and very rare, and only a few keyboard models use it (for example, Cherry G80 keys or old Nopoo Chocolate keyboards).

Currently, some manufacturers like Vortex use it but only to fill the keys of their keyboards in the area that should be illuminated, creating the PBT + POM Keycaps called Doubleshot .

Polycarbonate, for clear keycaps

There are also other materials used in PC keyboards, such as dry polycarbonate (PC). It is transparent plastic and is used by some manufacturers to make transparent caps that almost completely let the lighting from the switches through.

This material, however, is not very resistant and wears easily. Also, like ABS plastic, it tends to create shiny areas due to wear. It is widely used in brands of dubious origin and very cheap keyboards.

PPS, one of the rarest keyboard materials

PPS comes from Polyphenylene Sulfide (polyphenylene sulfide), and it is a fairly rare and rarely used plastic for keys. It is very thick, dense and hard, almost like glass, but like this it is also quite fragile although extremely resistant to wear and tear.

In addition, given their properties, keyboards that carry keycaps of this material do not even have the keys screen printed, since for a traditional screen printing it would not stick well to the keys, and a laser screen printing would end up damaging the structure and breaking the key. So, there really are no keyboards with this type of plastic from the factory, but there are some manufacturers that sell the keycaps separately, for users who really “crush” their keyboards and require maximum resistance.