Advances in conventional or mechanical HDDs are in full swing, as leading manufacturers have found new ways to increase performance, not just for today, but for the future. We have already talked about PMR, SMR, ePMR and now it is time to immerse ourselves in one of the two technologies for the coming years, specifically MAMR , what exactly is it and how does it work?

The definitive step of the manufacturers is going to focus almost certainly on what is known as MAMR, since it has certain advantages over HAMR. But to understand why the vast majority of these manufacturers, including WD, Seagate or Toshiba , are going for it, it is necessary to understand its basic fundamentals, which are well guarded at certain points.

The future is bright, MAMR will compete with HAMR for leadership

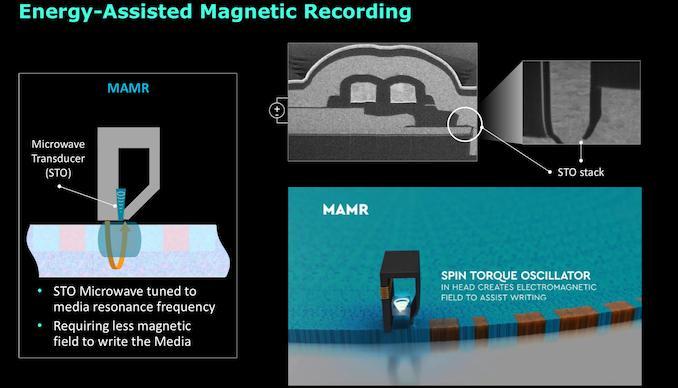

MAMR is the acronym for Microwave-assisted Magnetic Recording or translated into our language, microwave-assisted magnetic recording, and has gained quite a lot of popularity precisely for the way it records data on the decks: wave-based.

For this, a high-frequency magnetic field is applied to a magnetic recording medium while the recording process is carried out, which temporarily weakens the coercive force of the recording area, using for this what is known as the resonance phenomenon of the medium .

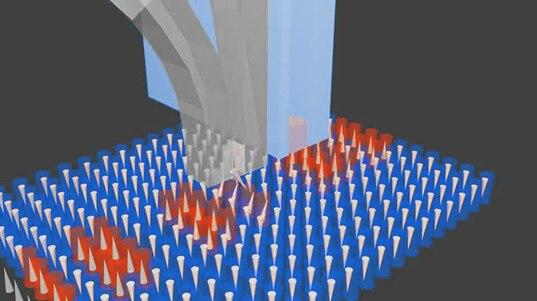

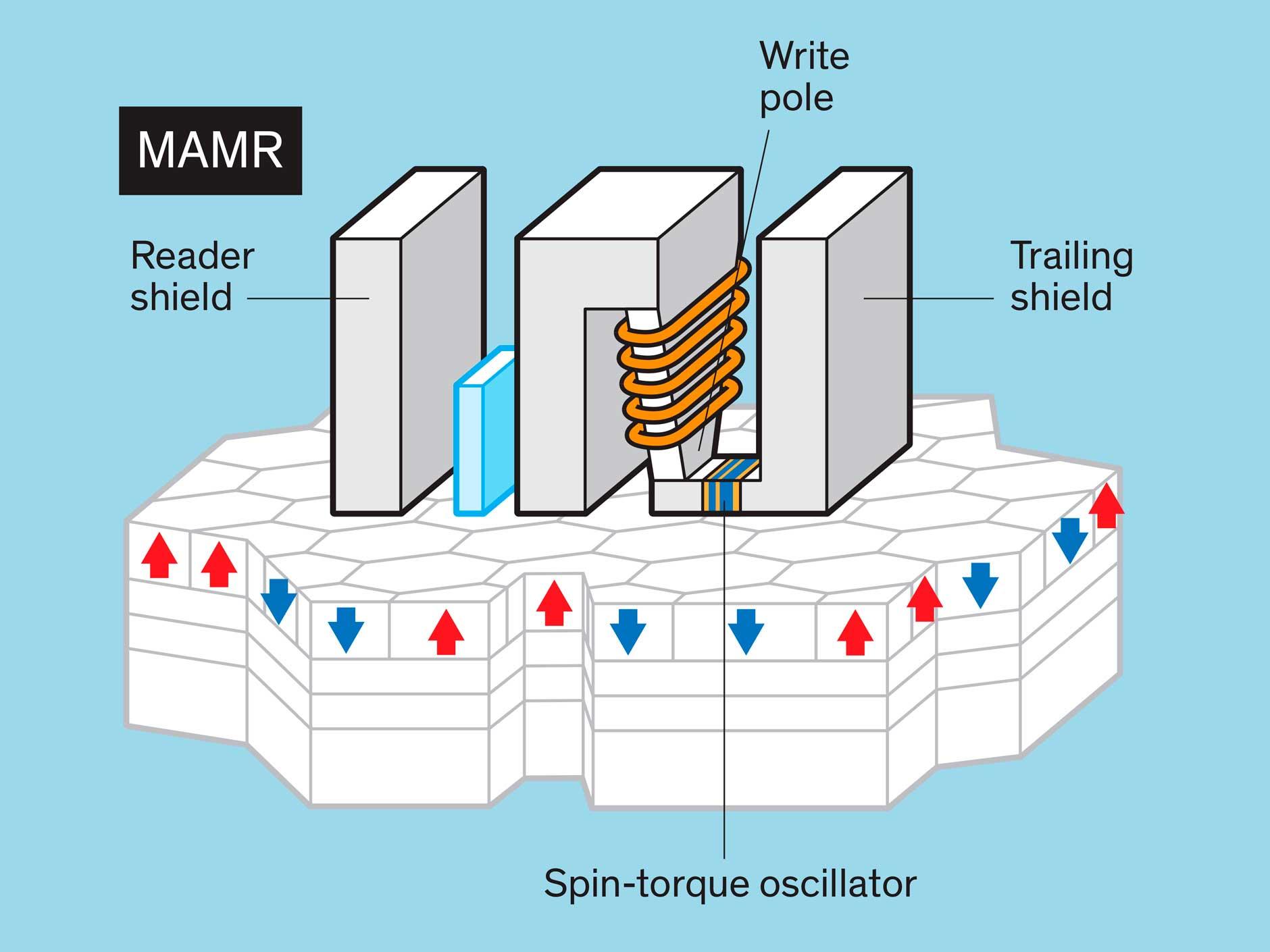

These microwaves achieve the resonance frequency of the medium in the microwave band itself, so the use of a microwave magnetic field oscillation layer is needed through what is known as a torque oscillator or STO (Spin-Torque-Oscilator)

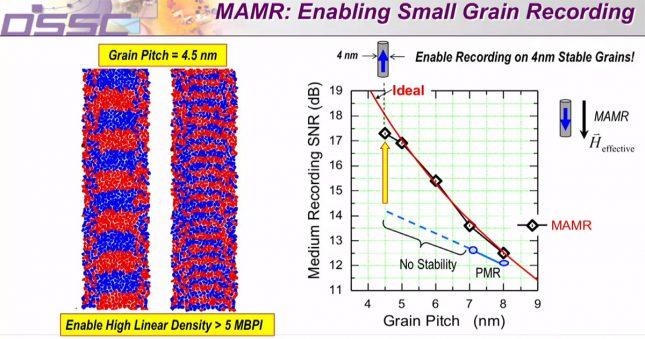

What we are trying to do is rotate the magnetization at high speed through the STO, which is in the writing head to generate waves in the range of 20 GHz to 40 GHz . With this, an auxiliary power is introduced to the current recording process resulting in more accurate recording with less energy use for the writing process.

Smaller and more accurate writing heads

If as a result we are able to write more accurately and with less power, the next step to take is to reduce the size of the write heads, which at the same time has another extra advantage: a significantly greater increase in capacity.

This capacity has to be endorsed by the plates, which have had to change their properties and materials to allow the highest precision of the heads. And it is that the heads have to consist of at least two magnetic layers, since as the current passes through the first one, it causes the spins of the electrons to polarize.

The second magnetic layer achieves an opposite magnetic alignment, so that the rotating polarized incoming electrons influence those that are inside the plate’s magnetic layer, managing to shift its magnetization slightly.

Since the frequency performed is the same as the resonance of the magnetic material that covers the plate, an oscillation is achieved at the points of the material so that they are easier to flip. Logically, the more frequently the STO is achieved, the more it will influence the smallest points of the plate material and the highest density will be achieved.

Therefore, all the advantages of MAMR will be based precisely on the improvements on the STO and on the chainrings, which are already being manufactured in Damascene.