Surely you have noticed the fact that when talking about lithographs or chip manufacturing processes, including processors, we are talking about nanometers when determining their dimensions. In this article we are going to explain why this unit of measurement is used and not another when referring to the transistors of the chips that we use in our daily lives, and we are going to do a retrospective view so that you can get an idea of how small or large is one of these famous nanometers.

As you well know, the chips that make up the interior of the processors are made up mostly of microscopic transistors, and they are so small that we have to measure them in nanometers. But before we put this in perspective, let’s see why the need to use such a small measure arose.

Nanolithography and the use of nanometers

Nanotechnology, nanometrics, nanobots … nowadays the prefix nano- is used so frequently that it is already something everyday, and in fact it is because precisely to incorporate so many thousands of transistors inside a chip a technique called nanolithography is used. From the Greek, the word can be divided into three parts: “nano” which means dwarf, “litho” which means stone and “spelling” which means to write, so literally nanolithography means “dwarf writing on stone”. But why?

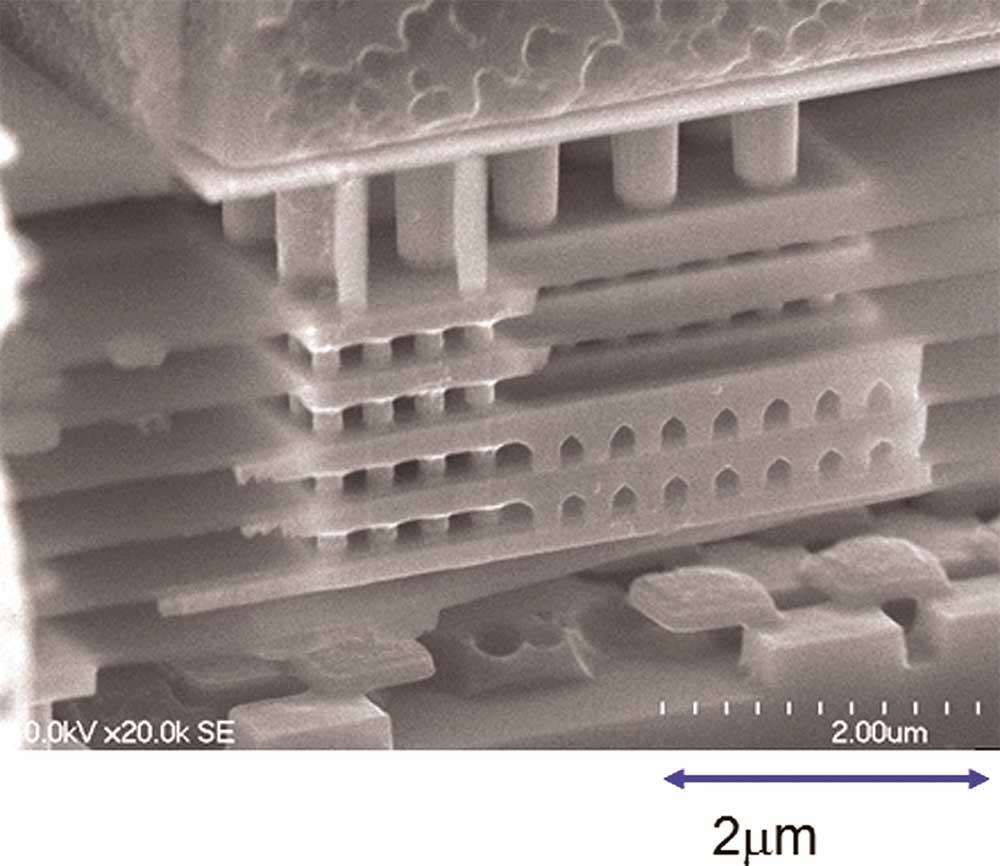

The field of nanolithography was born out of the need to increase the number of transistors in an integrated circuit to keep the well-known Moore’s Law alive. Although lithographic techniques have existed since the late 18th century, none were applied to nanoscale structures until the mid-1950s, and for that reason today the word has evolved to encompass the design of structures in the range of 10 – 9 to 10 −6 meters.

With the evolution of the semiconductor industry, the demand for techniques capable of producing micro- and nanoscale structures skyrocketed. Photolithography was applied to these structures for the first time in 1958, beginning the era of nanolithography and with it the need to start measuring magnitudes in nanometers. Since then, photolithography has become the most commercially successful technique capable of producing patterns of less than 100 nm.

How small is a nanometer?

When we talk about units of measurement, the most common are undoubtedly kilometers, meters, centimeters and millimeters. This is normal if we take into account that a human being measures slightly more than one and a half meters on average, or that our brain is between 13 and 17 centimeters long, while even something as small as a fly can measure between 5 and 8 millimeters. However, for measurements smaller than this it can be a bit difficult to imagine, especially if we tell you that a nanometer is equivalent to 0.000000001 meters, or 10 −9 m.

Let’s keep reducing the magnitudes: dust mites, which we can no longer see with the naked eye, are between 0.2 and 0.5 millimeters long, while a hair is around 80 microns (0.08 millimeters ). But that’s still a lot bigger than a nanometer, so we keep going down and we have, for example, the red blood cells we have in our blood measure between 5 and 7.5 micrometers, or even the bacteria have a length that goes from 0 , 5 to 5 microns.

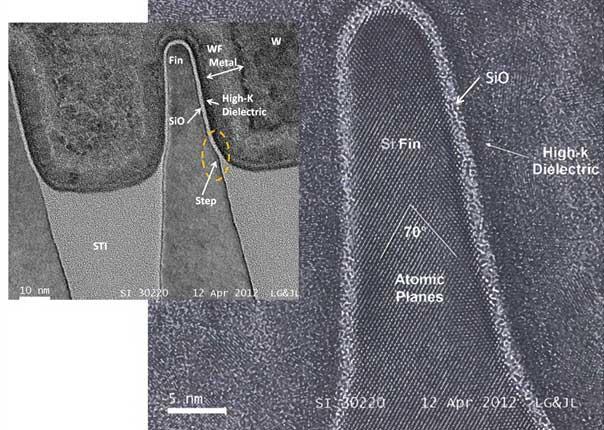

We have to reduce the size much more to run into viruses, whose scale starts at 100 nanometers at last. A dimension that seems common to hardware fans and even too large given the current times is 10 nm, which is precisely what proteins measure, or lipids measure about 5 nanometers. If we go down to a scale of 1 nanometer we have what measures, approximately, a DNA strand.

Realize the magnitude that we are handling here: the transistors that are being used in the current processors that we use every day are only a little larger than DNA, and that is to give you an idea if it could be reduced even more the size and reach 0.1 nanometers we would be talking about atomic scale, and not nanometric.

As you will already suppose, handling nanometers for the manufacture of chips is a prodigy and you will understand that it is becoming more complicated and expensive to handle such dimensions.