Many users wonder why the difference between TSMC and Intel processes. And it seems that the Taiwanese are quite ahead of the Americans due to the way they really name their lithographic processes. Why is Intel not able to manufacture a 7nm CPU today and TSMC does not stop selling chips to AMD?

To understand this simple concept, we must first know that all this is a product of marketing, no more, no less. The numerical reference of each lithographic process refers, in theory, to the size of the transistor, but this is not only not true, it is wildly incorrect.

To such an extent that nowadays in the industry no one really pays attention to the nanometer denominations, since they do not represent anything at all. So is it important that Intel cannot manufacture the same nomenclature as TSMC?

From nanometers to density, how do you compare lithographic processes?

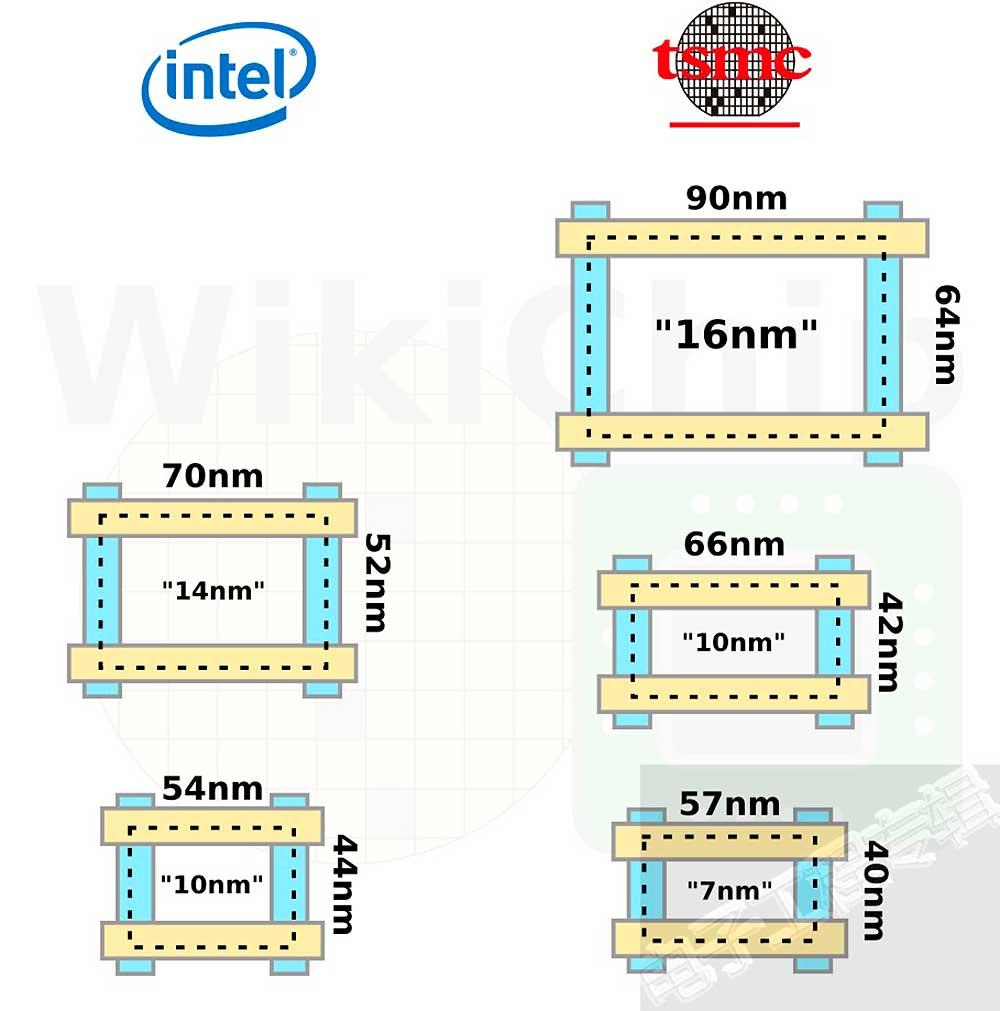

As we say, you have to forget about 14 nm, 10 nm or 7 nm, since this is not a metric of anything and is a pure and simple marketing name, nothing more. But when it comes to describing or trying to compare lithographic processes, there is a fact that is comparable and is decisive for, at least, trying to clarify which node is better or more complex.

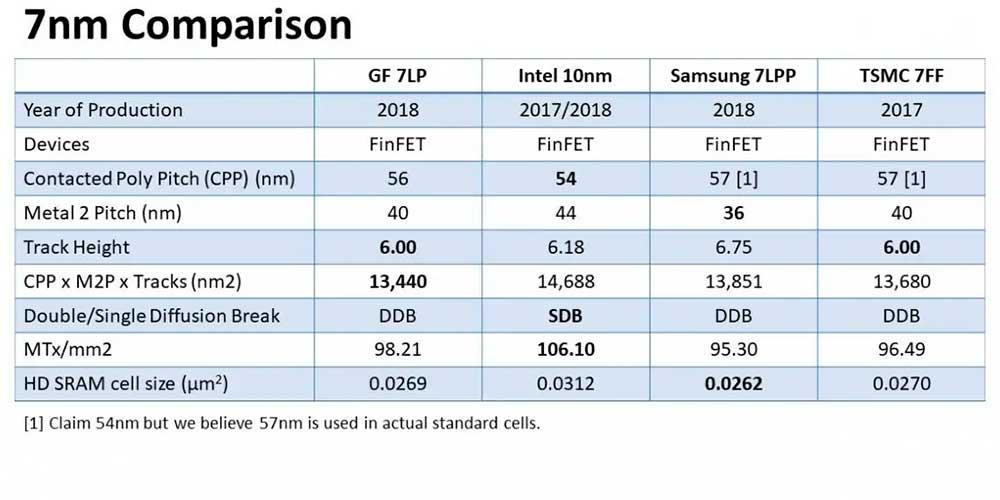

We logically speak of the density per million transistors in a square millimeter, also called and seen as MTx / mm2 . It is not the only parameter that we can compare far from it, since there are others such as the type of transistor, the CPP, Metal Pitch or the height of the tracks.

But although these parameters are important, they do not stop depending on each other to finally achieve what is intended in any lithographic leap: higher density, which indirectly refers to how small the transistors are, since the greater the number of them per square millimeter indicate smaller size and space between them, ergo, a more advanced node.

Why is not so much talk about density and about nanometers?

Well, for the same reasons that more reference will always be made to the frequency of a CPU than to its internal architecture: marketing once again. A number is more recognizable at first glance than understanding where the overall improvements are, but then why not talk about density if it is also a number?

Because it is a concept that is difficult to explain if you want to influence its improvements. In contrast, to say that a lithographic process is at 7 nm is to assume that transistors are at that size, easy and simple. Saying that the density is 96.49 MTx / mm2 for TSMC at 7nm is more difficult when it comes to marketing. Having understood this, we will explain the initial question of the article, since leaving marketing out, it has its crumb.

Why doesn’t Intel make 7nm CPUs like TSMC?

For many reasons. The first is that you don’t need it as its node at 10nm is denser than TSMC at 7nm (106.10 MTx / mm2 vs 96.49 MTx / mm2) both in high performance. That is, it manages to include more transistors in the same space as its rival and therefore is the leader in lithography.

Second, it is simply because you shouldn’t take the next step and jump from 10nm to 7nm. The investment made over the years and the delays suffered by this node force Intel to put the largest number of processors on the market to try to alleviate costs.

Just one piece of information about this, your FAB 42 has just opened its doors and is in full production, which means that you have to justify the investment and adapt at the same time other FABs for 7 nm, something complicated.

Lastly, Intel cannot force the machinery as hard to get to 7nm in production. It is true that it has Engineering Samples running through certain beta testers and that its 7nm EUV looks really good, but currently its FABs are not ready to launch high volume production, which would lead to an alarming shortage of CPUs and crazy prices.

It is partly to blame for ASML , which supplies the machines to all foundries in the world and with the pandemic is late, so it takes between 100 and 150 machines to produce these chips at industrial volume.